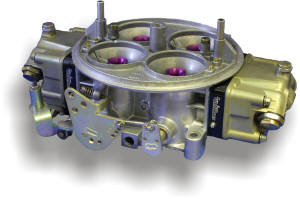

Below is some information about how a custom carburetor can benefit your engine

and a listing of packages we offer.

While carburetors can be very simple in operation, it is staggering to see how much technology has advanced their efficiency. Especially in the gauge legal type carburetors. They require very complex fixturing and machining to realize the gains we are seeing in our custom carburetors.

Exhaustive testing and development work led us to build a very useful testing bench JUST to test how well a power valve seals! We also rate these power valves with extreme accuracy to match them both primary and secondary on a 4 barrel, or to use them as a fine-tuning strategy on a 2 barrel or small 4 barrel. This is very basic, but is one more ingredient to how smooth our carburetors are on the race track.

We also pre-soak the floats we put in every carburetor. The weight and bueyency of the float controls the fuel level which is absolutely crucial to how the fuel is introduced to the main well on the carburetor.

All carburetors are tested on our wet flow bench, which draws air AND fluid thru the carburetor which allows testing of the discharge pattern from the booster and of course the air to fuel ratio.

There are many reasons to seek out a custom built carburetor. For starters, each component is scrutinized and massaged to the absolute peak performance. It is difficult to put into words how many little steps and adjustments take place when custom building or "blueprinting" a carburetor as there are too many to list. Simple things like how the throttle plate seals to the throttle bore, or how the secondary link ramps on the throttle shaft are just small items that all combined make the carburetor work smoothly together, giving it that improved power and throttle response over your competitors.

Holley Carburetors by Ryan Brown Performance

Our engine and chassis dynos are equipped with the standard sensors that allow us to measure the normal things such as fuel pressure, fuel flow, BSFC.... but also we have incorporated sensors and techniques to measure MAIN WELL PRESSURE, FLOAT BOWL PRESSURE, AIR BLEED SIGNAL.

The oval track carburetors we specialize in have unique G-Force modifications that will help the carburetor perform with even distribution even when pulling the high side loads seen on the race track.

You can rest assured that we are continually working all areas of the carburetor and can supply your race team with a carburetor that makes great power on the dyno... and better yet, is ultra smooth and consistent on the track.

Our CNC machine is used to do many complex operations that have proven to set these carburetors above all others.

Save $$$$ - We have extensive experience modifying Holley carburetors built by any of the Specialty Carb Shops. Depending on the condition, this will normally save money over the cost of a new unit by working with what you have.

As an option for our carburetors using the billet

metering blocks is our exclusive "Fuel Hood". Designed and machined in-house, this plate ensures we are picking up all fuel for main jets and power valve from an area of the float bowl that is filled with fuel when on the track. Shown is the primary block for an oval track carburetor, we also have a drag race version.